Queensland state owned generation company Stanwell has forged a major new partnership with the Australian-based maker of iron flow batteries that can provide long duration storage for a renewables-dominated grid.

The plan involves installing a 150 MW long duration big battery – with up to 14 hours of storage – using fully recyclable “flow battery” technology that is made in Queensland. It forms a key part of Stanwell’s renewable and storage plans for the next decade.

The sketch of the deal was outlined by state premier Anastassia Palaszczuk in her “state of the state” address on Wednesday, which included new announcements on wind farms, hydrogen gas generators, and the state’s $19 billion green energy plan.

“Work has also started on the Stanwell Clean Energy Hub that will use Maryborough-made iron flow batteries,” Palaszczuk said in her speech.

“Stanwell has also now entered into a partnership with Energy Storage Industries Asia Pacific to secure the first large scale deployment of locally made flow batteries in Australia.

“Stanwell and Energy Storage Industries are now working on an initial 150 megawatt battery project with the ongoing rights to purchase up to 200 megawatts per annum.”

Stanwell and ESI have already announced a deal to install a 1MW/10MWh iron flow battery storage system at the Stanwell coal generator, which followed on from a previous agreement by ESI to build a 1MW/5MWh iron flow battery system to be installed on the grid in Hervey Bay for Energy Queensland.

ESI is the Australian partner of Oregon-based iron flow battery company ESS Tech, which recently landed a major funding deal with US industrial giant Honeywell, and a $US300 million product order.

The flow batteries for the initial Stanwell pilot project are being delivered to its Future Energy and Innovation Training Hub near Rockhampton in twenty 12m-long battery modules. It will be the first iron flow battery in Australia and the largest in the world.

The iron flow batteries can provide up to 8-14 hours of energy storage, which makes them ideal for supporting and firming the electricity network during periods of high demand and low renewable energy generation.

They have a life of 25 years, are entirely recyclable and made with environmentally friendly electrolytes produced in Townsville.

The new agreement between the two companies revealed by Palaszczuck aims to deliver a 150MW battery installation into commercial operation as early as 2029.

The agreement also provides Stanwell with rights to purchase up to 200 MW of storage a year from ESI from 2026.

To deliver the Queensland Energy and Jobs Plan, Stanwell is building a renewable energy portfolio of at least 9 to 10 GW by 2035, and at least 3 to 3.5 GW of energy storage,” Stanwell chief executive office Michael O’Rourke said in an emailed statement.

“We’re excited about the possibilities of Queensland-made batteries playing a fundamental role providing Queensland homes and business with reliable, renewable energy.”

ESI managing director Stuart Parry said load iron flow batteries are essential for a smooth transition to a renewable energy future.

“The battery at Stanwell Clean Energy Hub is the first of many that will be deployed across the state to help stabilise energy supply from renewables and provide energy at night or when the sun doesn’t shine,” Parry said.

“Importantly, ESI’s batteries will be manufactured in a new $70 million Maryborough facility by skilled workers helping to drive a low carbon future for Australia and the Asia-Pacific region.”

“We look forward to working with Stanwell to deliver this and future projects, which are critical to supplying Queensland’s long-term energy needs.”

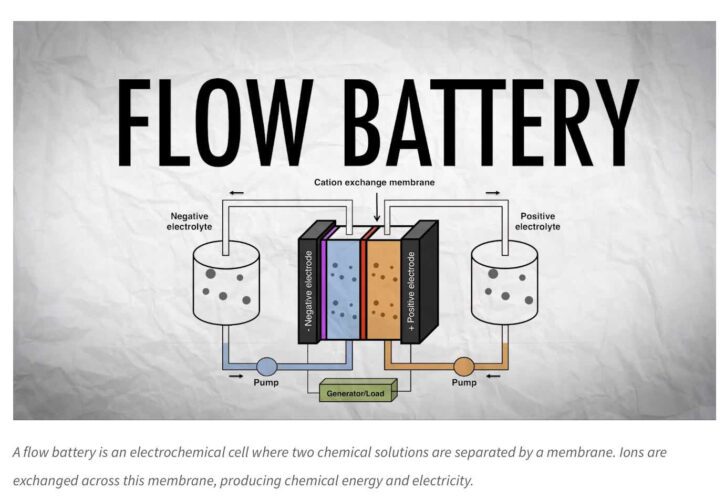

Note: ESS says iron flow batteries circulate liquid electrolytes to charge and discharge electrons via a process called a redox reaction.

The word “redox” is a contraction of the words “reduction,” which represents a gain of electrons, and “oxidation,” or a loss of electrons.

ESS uses the same electrolyte on both the negative and positive sides of the equation, eliminating cross-contamination and degradation. This is why ESS chemistry remains stable for an unlimited number of deep-cycle charge and discharge cycles.

Other “flow batteries”, such as those made by another Australian company Redflow, uses different minerals as electrolytes. Flow batteries do not use lithium or cobalt.

See also: CS Energy takes 50% stake in its first wind farm, in big step away from coal