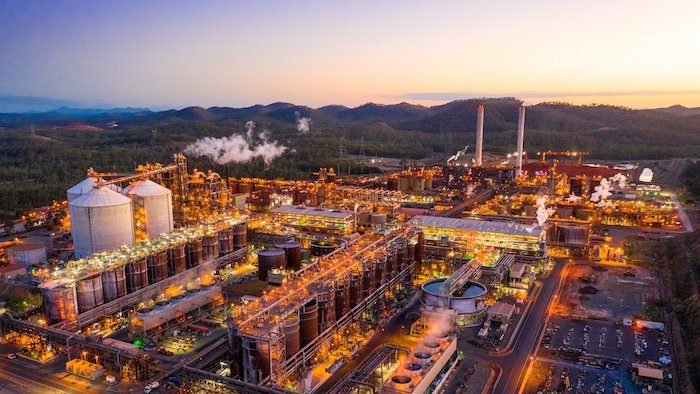

The federal government’s clean energy funding arm has kicked in $32.1 million to test hydrogen calcination technology that may be able to cut emissions at the Yarwun Alumina Refinery in Gladstone, Queensland.

The trial is of a 2.5 megawatt (MW) electrolyser to make about 250 tonnes of hydrogen annually that will be substituted for fossil gas in one of the refinery’s four calciners, using retrofitted hydrogen burners.

For the trial, the electrolyser will use the same power sources as the refinery does. Operator Sumitomo Corporation will surrender large-scale generation certificates (LGCs) to offset the emissions.

The project won’t be commissioned until 2025.

Alumina, derived from bauxite, is the precursor to aluminium.

Alumina refining is the energy and emissions intensive step in making aluminium and has long been one of the hardest to abate industries, due to few commercially feasible and technically advanced low emissions alternatives.

Alumina refining currently makes up about 3 per cent of Australia’s annual greenhouse gas emissions and consumes more than 221 petajoules of energy each year, more than the total energy consumption of Tasmania or the Northern Territory.

Some 95 percent of emissions are from the onsite consumption of fossil fuels for process heating.

Which is why the Australian Renewable Energy Agency (ARENA) stepped in to subsidise part of the total $111.1 million total cost of the Yarwun project.

Fortune 500 company Sumitomo, which made a Y565.2 billion ($6 billion) profit in fiscal 2022, will own and operate the subsidised electrolyser.

That hydrogen will be fed directly into the Yarwun plant which is opened by Rio Tinto, which reported an after tax profit of $12.42 billion in 2022.

Study suggests it could work

The Australian Renewable Energy Agency (ARENA) also supported Rio Tinto’s feasibility study with a $580,000 grant in 2021.

“Calcination is the last step in the alumina refining process, requiring temperatures in excess of 900C to remove chemically bound water that is associated with alumina,” the feasibility study said.

When using fossil gas, this part of the process creates about a third of all greenhouse gas emissions from alumina refining.

By using hydrogen instead, the calcination process produces steam which can be used for other parts of the refining process, according to the study.

ARENA focused on alumina

If the pilot is successful, it will be a significant step for the Australian alumina industry, says ARENA CEO Darren Miller in a statement.

“Paving the way for deployment across the industry, and underscoring the importance of low-cost green hydrogen to decarbonise our largest industrial emitters,” he said in a statement

Alumina refining is an area that ARENA has been watching, having published its Alumina Decarbonisation Roadmap in 2022.

It’s also funded Alcoa to test electric calcination — effectively an electric furnace — powered by renewable energy in 2022 and mechanical vapour recompression in 2021.

Other technologies it identified are using electric boilers to replace fossil fuel-made steam with purified steam, and on-site thermal energy storage.