UNSW Sydney projects have been awarded a glut of funding by the Australian Renewable Energy Agency (ARENA) to support research and development that will significantly reduce the cost of solar.

As reported this week, the funding is part of ARENA’s ‘Solar 30 30 30’ target, aimed at achieving 30% module efficiency and 30 cents-per-installed-watt at utility scale by 2030.

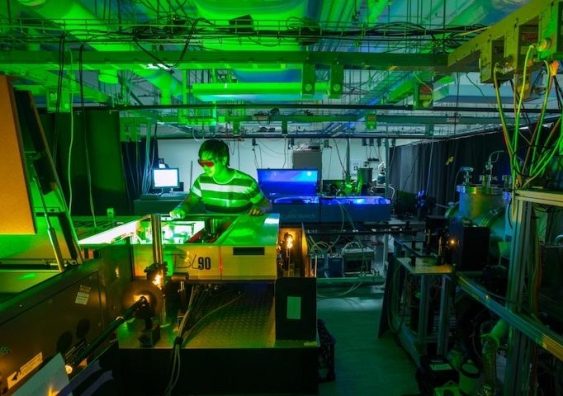

The researchers, from the School of Photovoltaic and Renewable Energy Engineering (SPREE), will receive more than $29 million across nine projects.

The winning projects include research into hybrid solar cells headed up by PV legend Scientia Professor Martin Green, a powerhouse in the Solar space who co-invented the PERC solar cell, found in roughly 75% of all solar panels operating today.

Let’s take a look at some of these projects in more detail.

Exciting exciton science: singlet fission solar cells

The agency has awarded $4.8 million to a project investigating the development of singlet fission solar cells.

Singlet fission is a reaction that could in theory make silicon solar cells much more efficient. That’s important, because conventional or ‘bare’ silicon, by far the most common semiconductor material used in solar cells, can only capture a limited amount of the sun’s energy. Singlet fission solar cells, if successful, could vault this threshold and surpass the critical 30% line that has (for the most part) plagued PV research.

The project, led by Professor Nicholas (Ned) Ekins-Daukes, builds on a decade of pre-existing singlet fission research at UNSW, and will push forward the development of the already-patented OMEGA Silicon technology.

The new technology takes advantage of the basic physics of a solar panel. When light hits a material, it generates an ‘excitation’ in the form of an exciton, which is the bound state of an electron and an electron hole. An electron hole, in physics-speak, is a quasiparticle characterised by the lack of an electron at a position where one could exist.

According to OMEGA, their technology harnesses singlet fission to generate two excitons from the single exciton originally produced when said photon hits the panel, increasing the efficiency of the reaction by a factor of two.

All-up, the team believe they can increase the absolute efficiency limit of a silicon solar cell from 34% to 45%, which would provide epic bang for your buck.

PERC/TOPCon Hybrids

In silicon solar technology, Passivated Emitter and Rear Cell (PERC) cells, invented at UNSW by the aforementioned Professor Green and his team and now dominating the solar PV marketplace, achieve a higher energy conversion efficiency by adding a dielectric passivation layer at the rear of the cell.

These layers or coatings prevent the loss of energy that occurs when photo-generated charge carriers recombine on the cell surface.

The biggest challenger to PERC cells in terms of increasing efficiency is a technology known as TOPCon (Tunnel Oxide Passivated Contact). TOPCon cells work in a similar way to PERC cells, except they have an added ultra-thin silicon dioxide layer as another barrier to the loss of unabsorbed light.

TOPCon cells are more efficient than PERC cells but at a higher cost, so Professor Green and his team are in the process of developing a hybrid solar cell, dubbed RJ-PERP, that fuses the two technologies. That project has been awarded a $3.7 million ARENA grant.

The cell would, according to the researchers, capture the best features of both technologies – making it more efficient than either – while avoiding the more expensive elements of TOPCon cells that blow out the costs.

Chalcogenide-Si tandem cells

Another $3.1 million of the funds were awarded to a project led by ARC Future Fellow Professor Xiaojing Hao that hopes to develop chalcegonide/silicon tandem cell technology.

Chalcegonide/silicon tandem cells are seen as a way to cut solar costs, combining the high efficiency of tandem cells – stemming from their ability to harness multiple bands of the solar spectrum – with the low costs of both silicon and chalcegonides, which are both abundant in the Earth’s crust.

By combining the best technologies from both silicon and chalcegonide cell research, Hao’s team hope to build high performance, cost-effective cells that can be scaled up rapidly. Watch this space.

Limiting industry reliance on silver

In 2021, the solar PV industry consumed approximately 13% of the annual global silver supply. Silver is a linchpin in the manufacture of most solar panels – the highly conductive metal is turned into a paste and loaded into each silicon wafer.

By some estimates, known silver reserves could run out within the next few decades, though there’s always the possibility of more being discovered or salvaged. Regardless, supply chain issues are coming, and they’ll drive up costs.

With that in mind, a team led by UNSW Scientia Fellow Associate Professor Brett Hallam is investigating a method to reduce the silver consumption of industrial PV manufacturing. The team will develop a novel screen-printing approach that they say could overcome the limitations of conventional design.

The team hopes to reduce silver consumption to 5 mg per watt (mg/W) for industrial solar cells. For comparison, the global PV industry’s average silver consumption in 2020 was 19.5 mg/W.

A machine-learning decision maker for solar O&M

The droids are coming to PV, with ARENA awarding $2.5 million to a project, led by UNSW’s Professor Ziv Hameiri, that will develop an automated decision-making platform for the O&M of utility-scale solar power plants.

Machine learning has been touted as a way to streamline the efficiency of industrial-scale solar plants, and various projects globally are trialling such systems.

The monitoring system being developed by the UNSW team will be informed by historical data form project participants, assembled into a nationwide performance database that tracks site information, weather data and electrical measurements.

The team hopes the system will be able to investigate degradation and predict rates of soiling – the accumulation of dirt and grime that impairs a solar panel’s efficiency. Ultimately, it will be able to make decisions that optimise an industrial farm’s performance, reducing the overall cost of energy by limiting O & M costs.

Materials, materials, materials

The PV sector relies heavily on a range of materials, including silicon, copper, aluminium, steel and concrete. A 2020 World Bank report estimated that up to 200 Mt of metals would be required for the sector under the International Energy Agency’s ideal Renewable Energy Roadmap scenario, which assumes production of 8.5 TW of PV energy by 2050.

All that demand for materials could drive up the LCOE.

With that in mind, Brett Hallam is heading up a second project, awarded $2.4 million by ARENA, that will conduct extensive modelling, including life-cycle analysis, yield analysis and LCOE calculations to address materials consumption in PV systems.

Ultimately, the project will (hopefully) develop strategies to mitigate both the soaring costs and environmental impact of increasingly in-demand resources, by developing PV modules that rely less heavily on various materials.